- +91-8882964379

- info@certilize.com

Set up of Construction and Demolition (C&D) Waste Recycling Plant

Introduction

India’s rapid urbanisation has dramatically increased the amount of construction and demolition (C&D) activities. Together with this growth comes an ever greater problem–more than one million tonnes of waste, including concrete fragments, bricks, stones, sand, wooden or metal construction debris. There is even plastic and plaster waste! According to figures from the Central Pollution Control Board (CPCB), India is currently producing at least 150 million tonnes of construction and demolition(C&D) waste. Annually, a significant portion ends up in illegal dumping sites, open landfills, or water bodies.

Given the rising problem, the Government of India, in its C&D Waste Management Rules, 2016, requires the scientific treatment of C&D waste. This presents a good opportunity for entrepreneurs and urban infrastructure players to set up large-scale Construction and Demolition Waste Recycling Plants.

CERTILIZE will provide end-to-end services to establish C&D waste processing centres, including licensing, machinery, plant layout designs, and architecture, as well as EPR advantages and marketing connections.

Licensed and certified Requirements

To establish a C&D waste recycling plant that complies with the relevant laws and organizations, approvals are needed:

Company registration

Sole proprietorship, joining a partnership or forming a limited liability group or company.

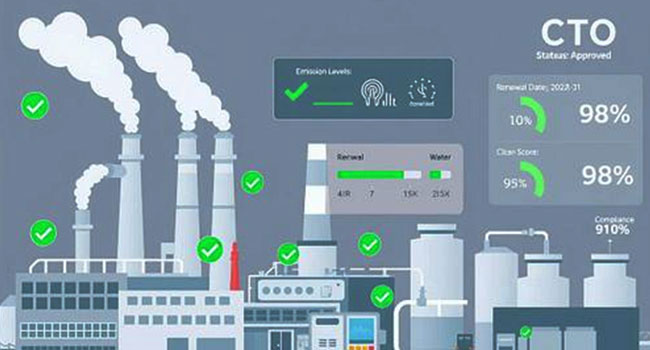

- CTE (Consent to Establish) and CTO (Consent to Operate), among others

Under the Water (Prevention and Control of Pollution) Act of 1974 and the Air Act of 1981

Authority: State Pollution Control Board (SPCB) - Authorization of C&D Waste Management Rules, 2016

Authority: Local Municipality Body or Urban Local Body ( ULB) - Business License / Business License / Trade License / Shop and Establishment Certificate

Municipality or Gram Panchayat - Factory License

In commercial plants, there are employees and powered machines - NOC of Fire and Safety

Necessary worker and equipment safety - Environmental Clearance (in case the plant capacity is >20 TPD)

Grantor: State Environmental Impact Assessment Authority (SEIAA) - GST Registration

Needed in the billing and the sale of recycled aggregates - EPR Registration

When the producers/importers process debris packaging - Urban Local Body MoU

In the case of procuring raw material (C&D waste) and land allocation

Machinery and Equipment – Names & Estimated Cost

A typical C&D waste recycling unit will process between 50 and 300 tons per day. Major equipment includes:

| Machine Name | Purpose | Approx. Cost (INR) |

| Jaw Crusher | Crushes concrete and bricks into smaller pieces | ₹10,00,000 – ₹20,00,000 |

| Vibratory Screening Unit | Segregates materials by size | ₹5,00,000 – ₹10,00,000 |

| Trommel Screen | Removes fines and debris | ₹3,00,000 – ₹6,00,000 |

| Magnetic Separator | Extracts metal particles | ₹2,00,000 |

| Air Separator | Removes lightweight plastic and paper debris | ₹2,50,000 |

| Belt Conveyors & Feeders | Transfers waste material | ₹3,00,000 |

| Water Sprinkler/Dust Suppressor | Controls dust pollution | ₹1,50,000 |

| Aggregate Washer (Optional) | Cleans reusable sand/aggregates | ₹4,00,000 |

Estimated concrete setup costs

- Small Plant (50 tpd): 4 million – 5 million

- Medium Plant (100 200 TPD): The cost of a medium plant is 80 Lakhs to 1.5 Cr

CERTILIZE supplies high-efficiency, low-maintenance machines with comprehensive commissioning and AMC facilities.

Waste recycling C&D process

- Pick-Up and Delivery

The C&D waste is gathered at the construction sites, demolitions and ULBs - Inspection of Weighing and Inspection

Input material is weighed and checked to ensure it is free of hazardous material (e.g. asbestos) - 2006-10-05 Crusher, Screening

Big debris (concrete, bricks) is crushed and processed on vibrating screens, broken and goes to:

Coarse aggregates

Sand and fine dust

Plastic, metal and wood - Metal and plastic recovery

Metal is collected with the help of magnetic separation, and plastics are separated through air separation - Washing Grading (optional)

- Storage and deagitating

The processed aggregates are stored and sold to the contractors and builders

Overview of the market- India and the world trends

- The urban construction segment in India is expanding at a rate of more than 8% CAGR.

- Cities such as Delhi, Mumbai, and Bengaluru generate 35-40 per cent of their C&D waste as municipal solid waste.

- The demand for recycled aggregates is being driven by Government Projects such as Smart Cities, AMRUT and Housing for All.

- Green materials are becoming common in use by private builders to satisfy environmental clearance standards.

Recycled Product Market:

- Road base: coarse and fine road base, pavement

- Manufactured sand (M-sand) production of bricks/blocks

- Recycled blocks and pavers

- Precast structure aggregates

- Landfill cover material and landscaping material

National Building Code of India now suggests as much as 25 per cent recycled aggregates in the construction of public structures.

EPR Benefits and Muni-C support

The government had pushed its EPR (Extended Producer Responsibility) and Circular Economy program:

- The construction companies and developers are being urged to dispose of C&D wastes to licensed recyclers.

- Some cities provide tipping fees for processing C&D waste

- Recyclers are collecting EPR credit in case they recycle packaging waste associated with construction work (plastic, metal, etc).

MoUs with Municipal Corporations may have to provide:

- Territories assignment

- Free raw material (wastes inflow)

- Gate fees or revenue share

CERTILIZE assists recyclers in enrolling under the EPR system of CPCB and connecting with large contractors, infrastructure developers, and brands.

What is the Reason to Choose CERTILIZE?

Having had experience in more than 200 recycling setups in India, CERTILIZE offers:

- Professional consultancy services concept to commissioning

- Legislation, environmental and license advice

- DPR feasibility study preparation

- Purchase of machinery from authorized vendors

- EPR & CSR Integration for Credit

- Plant layout, workflow planning and manpower planning

Either through a model of partnership with the state or a private plant on rented land, CERTILIZE guarantees success and sustainable operations.

C&D Plant Setup collaborate with CERTILIZE

A significant business opportunity lies in plain view construction waste. Establishing a C&D waste recycling facility not only establishes a business but also promotes sustainability.

Frequently Asked Questions

-

What does C&D waste consist of?

Bricks, tiles, concrete, sand, metal, plastic, glass, wood, gypsum and other debris.

-

Do we have to recycle C&D waste?

Yes. With the 2016 Rules, ULBs have to set up or enter into a partnership with recycling plants.

-

How would I be able to have a steady supply of raw material?

Regular flow by signing a MoU with municipalities or construction contractors.

-

What is the use of recycled aggregates?

Sub soil, road works, and bricks, back filling, concrete mix (partially ratio).

-

Do they have subsidies or schemes of support?

There are urban bodies that produce land/tipping fees. CGTMSE provides loans on machinery to MSMEs.

-

Is there land to establish plants?

Yes, it can be via MoUs with ULBs or industrial areas (premises of 10,000 to 30,000 sq. ft. are necessary).

-

What will happen to the environment?

Eases the load on landfills, eliminates illegal dumping, and decreases the demand for virgin stone/sand.

-

Is it possible to have certification of my recycled product?

Yes. BIS-certified aggregates may be applied to any public project.

-

How much money will such a plant make?

Taking between 2-3 years to pay back, depending on capacity, contracts, and the sale of materials.

-

Is it possible to export recycled aggregates or blocks?

It is currently restricted by bulk and margin, and there is a pressing need in Bangladesh and the UAE.