- +91-8882964379

- info@certilize.com

Ship Recycling Plant Setup

Introduction

The world maritime sector creates hundreds of decommissioned vessels per annum such as cargo ships, oil tankers, and naval vessels. Ship breaking, also called ship recycling, is defined as the act of dismantling old ships to recover valuable metals (such as steel, copper, aluminium, brass) and other machinery/marine equipment that can be reused. India is the world leader in recycling of ships, especially at Alang in Gujarat — the largest ship breaking yard in the world — having a huge coastline and a strong retail steel trade.

This industry has been regulated through the Recycling of Ships Act, 2019, harmonized with the Hong Kong International Convention on the Safe and Environmentally Sound Recycling of Ships. As sustainable waste management, green production of steel, and EPR obligations become increasingly significant, the establishment of a Ship Recycling Plant offers a business opportunity to participate in the high-volume, high-value circular economy.

CERTILIZE offers complete turnkey services in establishing a compliant, effective, and lucrative ship recycling yard anywhere along the Indian coast.

Licenses and Certifications

Setting up a ship recycling yard in India requires multiple legal, environmental, and marine approvals:

- Company Registration – Ownership, Partnership, LLP, or Pvt. Ltd. (Ministry of Corporate Affairs or Udyam)

- Yard Recycling Permission – Under Recycling of Ships Act, 2019 (Directorate General of Shipping – DGS)

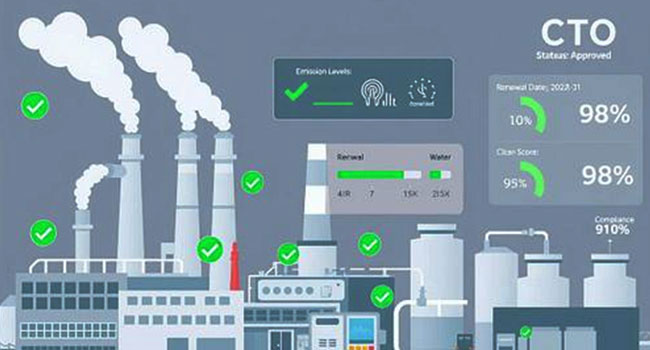

- Consent to Establish (CTE) / Consent to Operate (CTO) – Under Water and Air Acts (State Pollution Control Board – SPCB)

- Dangerous Waste Management Permit – For asbestos, chemical, and oil residue management (SPCB/CPCB)

- Ship Recycling Facility Plan (SRFP) – Layout, pollution control, safety, and emergency plans (DGS)

- Ship Recycling License – Required for each vessel before beaching and cutting

- Occupational Safety & Health Compliance – First-aid, PPEs, and worker training

- Environmental Impact Assessment (EIA) – Mandatory for yards handling >30,000 DWT capacity

- NOC for Fire and Safety – Due to inflammable materials onboard ships

- EPR Registration (Optional) – For processing producer-bound EEE or plastic waste

CERTILIZE handles documentation, safety SOPs, layout planning, and follow-ups with marine and environmental authorities.

Machinery & Equipment – Name and Estimated Cost

| Machine Name | Purpose | Approximate Cost (INR) |

|---|---|---|

| Oxy-Fuel Cutting Torches & Kits | Cutting ship hulls and internal parts | ₹5,00,000 |

| Hydraulic Shears | Cutting thick metal and beams | ₹10,00,000 – ₹20,00,000 |

| Cranes (Mobile & Gantry) | Lifting heavy parts and engines | ₹25,00,000 – ₹50,00,000 |

| Winches and Capstans | Pulling ships towards the shore/beaching | ₹10,00,000 |

| Air Compressors | For pneumatic tools and cleaning | ₹2,00,000 |

| Oil & Sludge Recovery Systems | Extracting fuel and chemicals safely | ₹3,00,000 |

| Waste Segregation Units | Sorting metal, plastic, e-waste, oil drums | ₹5,00,000 |

| Gas Detectors & Safety Monitors | Detecting flammable and toxic gases | ₹1,00,000 |

| PPE Kits, Safety Equipment | For hazardous tasks | ₹2,00,000 |

Total Plant Setup Cost: ₹1.2 to 3 Crores (varies by capacity and equipment type)

CERTILIZE provides IS-approved and DGS-rated equipment along with installation and staff training.

Ship Recycling: Process Flow

- Buy and Records – Purchase decommissioned vessels via auction or direct from shipping lines; obtain Inventory of Hazardous Materials (IHM).

- Pre-Beaching Inspection – DGS and SPCB verify IHM and emergency preparedness.

- Beaching Operation – Beach ship at approved yard using tide and winches.

- Dismantling – Cutting hull sections, structures, steel sheets, pipes, equipment, and machinery.

- Hazardous Waste Handling – Manage asbestos, oil sludge, batteries, and electronics per regulations.

- Segregation & Sale – Steel to re-rolling mills; machinery, pumps, and furniture to secondary markets.

- Reporting & Site Cleaning – Compliance report submitted to authorities.

Market Overview

- India handles over 30% of global ship recycling.

- Alang (Gujarat) has recycled 6000+ ships.

- Produces ~4 million tonnes of scrap annually.

- Creates over 1 lakh jobs directly and indirectly.

- Growing demand for green ship recycling.

Recovered Materials Market

- Steel plates – Construction and fabrication

- Copper wire – Sent to metal recyclers

- Valves/pumps – Reconditioned and sold

- Electronics – Sent to e-waste plants

Key Buyers

- Re-rolling mills

- Metal scrap sellers

- E-waste recyclers

- Machinery rebuilders

Future Trends

- Hong Kong Convention ratification → more compliance

- Rising green steel demand

- ESG-linked financing enabling green loans

Sustainability & EPR Advantages

Ship recyclers indirectly benefit from EPR (plastic/e-waste) via recovered materials such as electronics, plastics, and batteries when processed by authorized recyclers. This also generates green credits and supports carbon neutrality goals.

- Collaborate with brands for large-scale recycling

- Seek CSR funding for worker safety and training

- Register as CPCB-approved end-processors

CERTILIZE offers EPR structuring and CSR matching for recyclers.

Why CERTILIZE?

We specialize in setting up environmentally compliant ship breaking yards in India:

- Licenses: DGS, SPCB, Customs

- SRFP preparation

- Machinery procurement and installation

- Hazardous waste SOPs and worker training

- EPR/CSR documentation

Support for new yards in Gujarat, Maharashtra, Andhra Pradesh, Odisha, and Tamil Nadu — including dismantling, resale, and trading yards.

Let’s Build a Sustainable Ship Recycling Industry

India has the potential to lead the world in green ship breaking. With favorable laws and a strong market, now is the best time to start.

Frequently Asked Questions

-

Is ship recycling legal in India?

Yes, under the Recycling of Ships Act, 2019, aligned with international conventions.

-

Do I need a license for each ship?

Yes, each ship requires specific authorization.

-

What is IHM?

Inventory of Hazardous Materials – a mandatory list of dangerous onboard products verified before recycling.

-

How long does dismantling take?

Between 30 to 90 days depending on ship size, weather, and manpower.

-

Where can dismantled materials be sold?

To scrap dealers, re-rollers, and secondary markets.

-

Can recovered steel or parts be exported?

Yes, with DGFT license and BIS compliance.

-

What safety measures are needed?

PPE, gas leak detection, asbestos handling, fire safety, and emergency drills.

-

What is the profit margin?

Typically 8–15% based on ship quality, scrap prices, and resale efficiency.

-

What size yard is required?

Minimum 2–5 acres of coastal land with water access.

-

Are subsidies or incentives available?

Yes, green shipyards may get priority leasing, ESG funding, and carbon offset partnerships.